Multinationals face mounting pressure to better understand their supply chains and to eradicate their roots in armed conflict, slavery or child labour.

But it’s not easy. Minerals sourced from conflict-affected regions are often mixed in with regular minerals. Poor working conditions at suppliers' factories are not always immediately visible. While at the same time supply-chains are getting more complex.

Another issue around supply-chain management today is that data-collection is centralised and often, documented on paper. As a result, information cannot be shared instantly across the various, potentially-competing parties in the chain - or indeed, with the consumer.

This has led to major companies like IBM rolling out blockchain-based, supply-chain pilots, counting Nestle, Vodafone and Volkswagen among its partner-firms.

The use of blockchain theoretically gives operators a sort-of shared Google doc which is decentralised and unchangeable, where users can input data about the tagged goods and their movements. By making the database immutable, blockchains account for competing interests and parties' resistance to sharing information.

But IBM isn't alone.

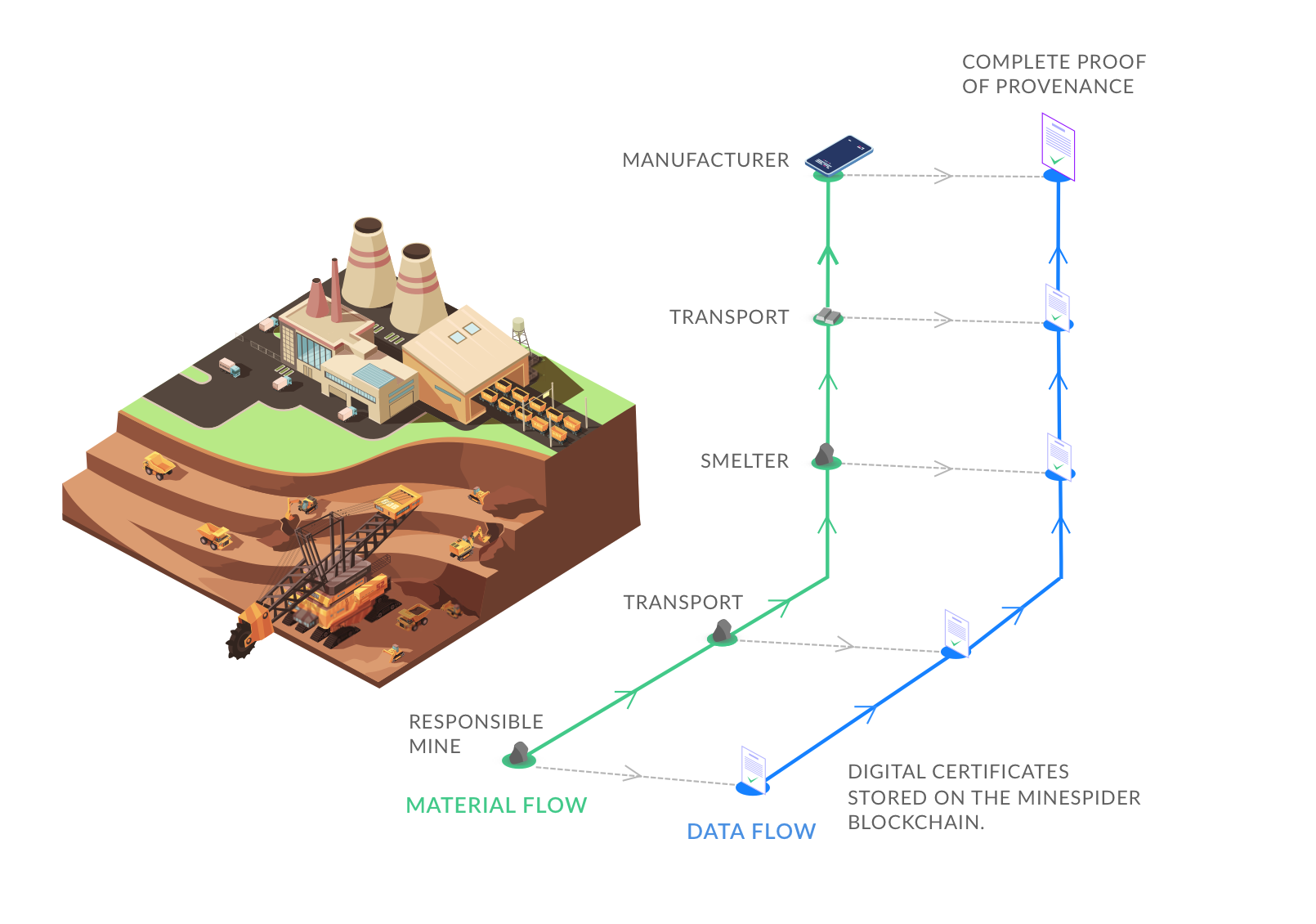

Startups are also working to help companies better understand the source of their minerals and textiles, using blockchain. Among them is Minespider, a Berlin-based startup that helps big brands trace the origin of raw materials, particularly conflict-minerals like gold, tin and cobalt.

Most recently, Minespider started on a pilot project to track the source of lead with German automaker Volkswagen.

“We built a way of transmitting secure data so that certain parts of the data are transparent and can be seen up the supply chain,” says Nathan Williams, founder and chief executive of Minespider.

The Minespider protocol allows brands to track the exact quantity of goods originating from each actor in the supply chain, utilising the Ethereum blockchain.

OURZ is another blockchain-based platform that provides supply-chain data to retailers. Using the app, retailers can "communicate [their] selling needs to the producer of the raw material in real-time,” explains OURZ's founder Antoni Hauptmann, which he says saves retailers time and money.

An imperfect fix?

Still, blockchain solutions are imperfect.

Supply chain management systems rely on the input of correct data by the individuals collecting the information. Companies might work with third-party certifiers and auditing companies on site, but the process is not infallible. Regardless of whether something is authenticated on the blockchain or not, bad information can be entered at source.

It's also worth remembering that these initiatives are still pilots, and there is still a long way to go technologically for blockchain to be the pillar of major supply chains.

That's part of the reason why Sustainabill, a German startup that focuses on fashion supply-chains. doesn't use blockchain technology but a cloud-platform.

“For us, it is about a flexible and innovative database system that allows suppliers to share some data to customer A and other data to customer B,” says Klaus Wiesen, cofounder and chief executive of Sustainabill. “Blockchain itself only ensures data integrity so that nothing can be manipulated but it is not the enabling technology to make supply chains transparent.”

Regardless of the limitations however, companies around the world are keen to experiment with blockchain-solutions. For instance, supermarket giant Carrefour currently uses IBM's blockchain-tracker for 20 food groups including chicken, eggs, and fruit. More importantly, the company seems to be pleased with the results according to a Reuters report. As all the data is digitised and on a public ledger, "customers can scan a QR barcode on a pomelo grapefruit with their phone and find out the date of harvest, location of cultivation, the owner of the plot, when it was packed, how long it took to transport to Europe and tips on how to prepare it."

Meanwhile, Minespider distinguishes itself by offering a hybrid level of transparency. The company stores potentially-sensitive data away from the public Ethereum blockchain to protect against competitors accessing the data.

“Other parts of the data are public and can be seen by everybody and a third segment is private and can only be seen by the immediate customers," Williams explained.

Part of a bigger picture

In short, cloud and blockchain solutions can help companies hold supply chains actors accountable. But of course, technology alone cannot eliminate child labour, slavery or environmental damage in production.

“Traceability solves the problem for individual companies,” says Minespider-founder Williams. “But solving the problem of the whole industry is much harder and involves collaboration.”

To make an impact, responsible sourcing has to be adopted as the industry standard, he points out.

“It is going to be about integrating this into workflows such that people expect this type of data and are comfortable working together with the same decentralised system.”

Moreover, this requires ongoing pressure from consumers, says Klaus Wiesen, cofounder and chief executive of Sustainabill, as this shapes investors' outlook.

“With the high chance of upcoming CO2 taxes and the big risk of child labour, stakeholders want to know more about the origin of the product. Otherwise, they run a big risk when investing," he says.

“The industry has to align their standards and settle on the same data requirements. The entire topic is about collaboration.”