When you sit down at your desk and open your shiny laptop, you might not consider that such a beacon of modern innovation began its life in a family-run business with five employees that still runs its operations on a whiteboard.

Despite the blistering pace of progress in modern product design, the places where those materials are made remain stuck in the 20th century.

“It's the world's largest cottage industry. 95% of the factories in this industry have fewer than five employees. It's crazy. It's so difficult to scale these factories up because everything is manual,” says Theo Saville, cofounder and CEO at London-based CloudNC, a startup using AI to automate manual processes in factories.

“No one has innovated in this space in two decades.”

Saville is just one of many entrepreneurs using various AI approaches to try and revolutionise the global manufacturing sector. Given the size of the prize, it is no wonder.

Sleeping giant

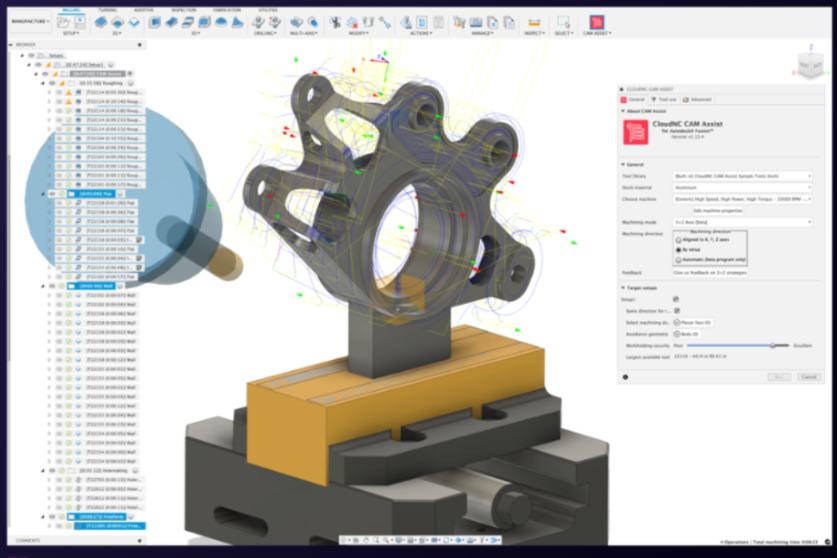

CloudNC focuses on an area of manufacturing known as CNC (computer numerical control) machining: the process of turning raw lumps of metal into the base components needed to build most things.

“It’s the biggest industry that no one's ever heard of. Roughly a trillion dollars worth of components are made by these machines every year,” says Saville.

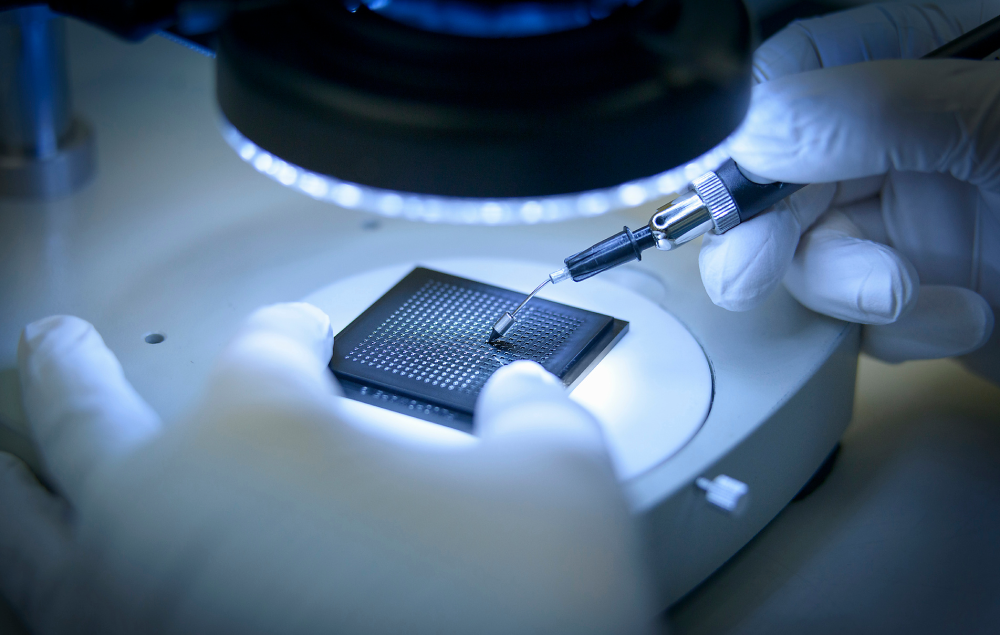

CNC machines make parts for aeroplanes, cars, oil and gas rigs, as well as for laptops and mobile phones.

“If you're touching a piece of plastic, it was made in a mould made by CNC machines. It's the beginning of all manufacturing,” he says.

But despite how essential these machines are to cutting-edge technology, they’re still controlled using software that looks like it'd be more at home in the era of MSN Messenger, as Saville demonstrates on a video call.

To program a machine to cut a metal part from a raw block, a trained professional has to input up to 4k operational instructions, covering everything from what type of cutting tool to use, to what pattern it should follow, to how quickly it should cut, and so on.

CloudNC is using AI to fast-track this process, automatically programming those instructions to get the system around 80% of the way before an expert operator steps in for the finishing touches.

Saville says that his company’s tech can save a worker around five hours of work per part they’re designing, allowing factories to meet demand quicker, as well as addressing a shrinking workforce that very few young people are joining.

“About half of the people in the industry worldwide will be retired in the next 15 years whilst demand doubles and there is no alternative process for this industry,” he says.

“So what's going to happen? Is manufacturing just going to stop working? Maybe.”

Living in a generative world

CloudNC says that since launching its AI-powered software tool a little over six months ago it’s got “hundreds” of paying customers. The company raised a $45m Series B round from investors including Atomico and Lockheed Martin.

Saville explains how his company is bucking the investor hype trend of the past 18 months by not building products with generative models, using what he calls more “classical” fields of AI. That’s because systems like large language models (LLMS) which power the likes of ChatGPT are known to “hallucinate” or make mistakes, something that’s not an option when you’re making precision parts.

But not all founders are so GenAI shy.

Jonas Schneider is the founder of German startup Daedalus, which raised a $21m Series A this month. Rather than modernising processes in existing manufacturing facilities, it plans to build AI-controlled factories.

Given that Schneider was one of OpenAI’s first engineers, it’s perhaps no shock that he sees room for using generative models in the process.

He tells Sifted that, where companies like CloudNC are focusing on one very specific part of the manufacturing value chain, with Daedalus’s autonomous factories he wants to use AI to address broader issues in the production line.

Daedalus’ technology will let users communicate with its system via natural language to request: “I need to make a hinge for this part that needs to be thin in these places,” to work out the best way the machines in the factory can make it.”

It uses a combination of a stock LLM to interpret what Schneider calls this kind of “fuzzy” description and then combines it with a proprietary dataset to generate the best plan it can for making that part.

“We basically look at these like fuzzy descriptions of the parts, and then compare them to fuzzy descriptions of other parts that we've made before,” he explains.

“For these previous parts, we have the fuzzy description, but we also have the actual concrete decisions that were made of which tools that we selected and which parameters we used.”

The bigger picture

Schneider says that this kind of bespoke AI-generated approach to manufacturing is best suited to use cases where you need a small number of high-value parts, rather than a mass-produced product like a phone or a laptop.

These are things like components for specialised semiconductor production machines or, on the other end of the spectrum, wheels for roller coasters. Daedalus says it’ll be able to make them with higher reliability than traditional, human-run factories.

And even if it’s only addressing one niche of this market, the opportunities are still huge.

Romanian-founded UiPath — which listed at a $35bn valuation in 2021 — has been using AI to help companies automate their processes for nearly 20 years. The manufacturing sector is a big part of that.

“It's a big numbers game. Globally, manufacturing is about 20% of GDP per country. In countries like Germany or Japan with a big industrial base, it’s close to 30 to 35%,” says Sebastian Seutter, UiPath’s global head of manufacturing.

French multinational energy company Schneider Electric, for example, which manufactures products for the energy grid like batteries, has sped its supply chain processes from four hours to a matter of minutes.

Seutter explains that manufacturing represents a significant proportion of UiPath’s client base, and it’s hardly surprising when you consider the types of potential clients that are up for grabs.

“Of the Global 1000 companies, the most prestigious companies in the world, there are some 450 manufacturing companies,” he says. “That tells you about where the pockets of value sit.”