Emma Watson, the Harry Potter star-turned-campaigner, is backing a wizard way to solve the world’s plastic crisis, backing a company with a novel way of making biodegradable plastics at the same price as fossil fuel-based materials.

Watson, who is also UN Women Goodwill ambassador, is part of a high-powered group of investors — including Twitter founder Biz Stone as well as VC firm Atomico — putting £12.5m into FabricNano, a two-year-old company that has so far been operating in stealth mode.

FabricNano has developed a cell-free way of manufacturing alternatives to fossil fuel-based plastic and chemicals — much more cheaply and at greater scale than has been possible before. The first products made this way could be on the market anywhere between a year to 18 months.

Bioplastics in themselves are not new — various companies such as Ginko Bioworks and Zymergen have been creating bacteria that can produce plastic alternatives through a form of fermentation. Microorganisms like yeast and bacteria can be modified to produce chemicals and plastic components, in much the same way that they have produced beer for the brewing industry for millennia.

Fermentation is artisanal, it isn’t scalable.

The problem with fermentation is that it is expensive, says Grant Aarons, CEO and cofounder of FabricNano. Fermentation can produce chemicals at around a $20 per kilo price point — compared to a $2 per kilo cost for producing conventional petrochemical products. Until you get the price down, they will not be a viable replacement.

This is obvious in the numbers. We produce more than 380m tonnes of plastic a year, but bioplastic production is estimated to be less than 3m tonnes — a fraction of a percent of the total.

“Fermentation is artisanal, it isn’t scalable,” says Aarons.

FabricNano says it can bring the production prices down with new technology that takes the living organism completely out of the equation. The company creates the same series of enzyme reactions that normally occur inside the cell, just without the cell.

If you want to know exactly how they do it, it’s time to get extremely geeky for a moment. Where do these enzymes sit when they are no longer conveniently housed inside a yeast cell or a bacterium? And how does FabricNano make sure that the enzymes are in exactly the right sequence for producing the material without the biological processes inside the yeast cell directing proceedings?

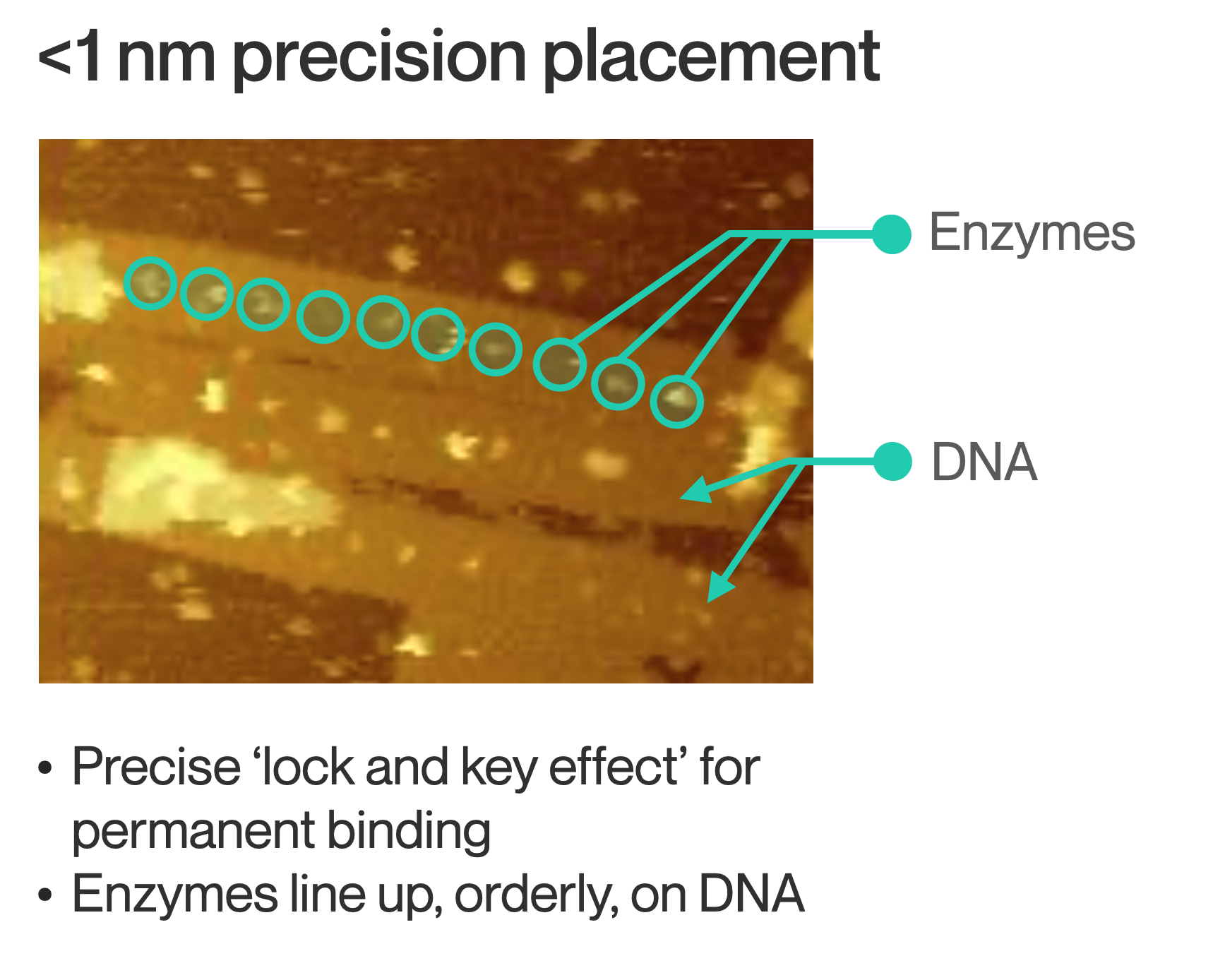

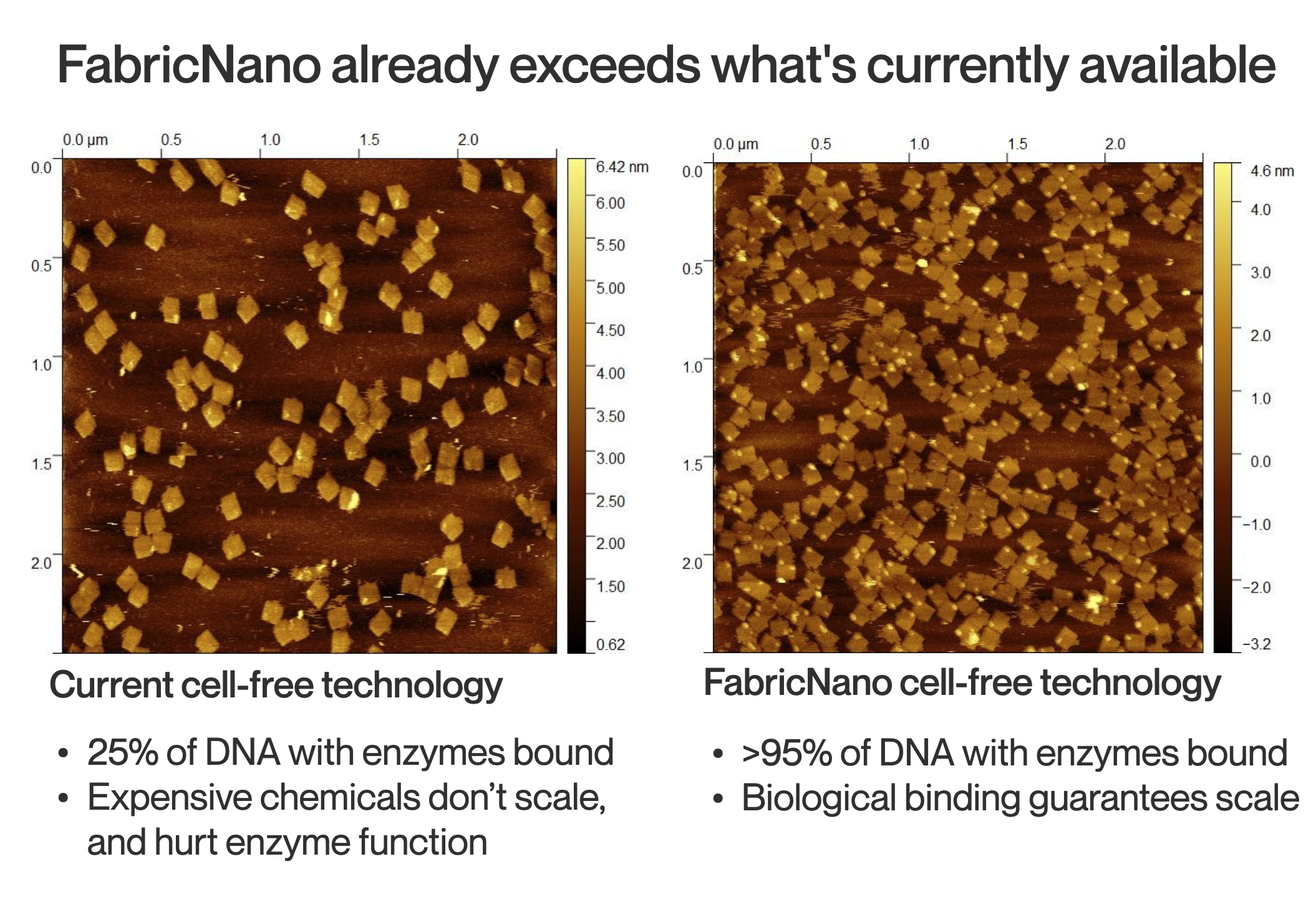

This is the company’s secret sauce: the sequence of enzymes is placed onto a fabric sheet woven out of a strand of DNA. Researchers have been working DNA into shapes for some time — this is not new — but FabricNano has figured out how to produce this woven DNA fabric much more cheaply than any other company, using it for the precision placement of the enzyme sequences.

We have a greater level of precision than the semiconductor industry.

“We can place one protein less than one nanometre from another on the DNA fabric. That’s a greater level of precision than the semiconductor industry, which works in seven nanometres,” says Aarons.

Under an electron microscope, this looks like a series of small dots on a ticker-tape of DNA. To the naked eye, the end-product looks like a white powder, but each speck of that powder is a highly engineered, microscopic production line for making bioplastic.

It’s almost worthy of inclusion among the potions at the Hogwarts Wizarding School. After all, as science fiction writer Arthur C. Clarke put it, any sufficiently advanced technology is indistinguishable from magic.

But more importantly, this technique is much more efficient than fermentation. Organisms generally only convert about 40% of the feedstock (such as sugar) into the finished product, and will produce impurities in the process: for example, some troublesome chemicals that contribute hangover when you drink alcohol.

“With cellular fermentation, there are always impurities, which you can put up with if its beer — they might give you a headache, but that’s fine. But it becomes a problem if you are manufacturing chemicals,” says Aarons.

Aarons says he believes the efficiency is such that bioplastics could be made in that $2 per kilo range that regular plastics cost to make. An additional bonus is that the raw material for making bioplastic could be glycerol, a waste product from the creation of biodiesel. Glycerol is mostly just burned today as there is little use for it — turning it into a bioplastics feedstock would be solving two waste problems in one.

In 10 years time we will look back and say that synthetic biology was one of the biggest things to impact the world.

“In 10 years time we will look back and say that synthetic biology was one of the biggest things to impact the world,” says Siraj Khaliq, partner at Atomico, who will join FabricNano’s board as part of the deal.

“This company’s ambition is no less than being the biggest chemical producer in the world, just doing it in a green way. It is not going to be a straight line from here, but I do believe that there will already be commercial applications of this in the market.”

The funding brings the company’s total investment to $16m. Aarons says the funding will allow them to expand the team to 30 people and move to a lab better suited for getting the product ready for commercialisation. In addition to chemicals and bioplastics , FabricNano plans to produce acrylics and antibiotics with its cell-free system.

The round was led by Atomico, with participation from existing investors Backed, Hoxton Ventures and Entrepreneur First (FabricNano was born out of a 2018 EF cohort, where Aarons met his cofounder Ferdinando Randisi). Also joining the round as angel investors were former Bayer CEO Alexander Moscho; Michael Stoppelman former SVP of engineering at Yelp; Elvie founder Tania Boler; and Vijay Pandurangan, former Twitter NY engineering site lead.